Laser Sensors

Due to their high resolution laser sensors are ideal for non-contact precision measurement of distance, route and position. Through an advanced analysis method the electronics of the laser sensor calculates the exact distance to the measurement object by means of triangulation or phase shift. The compact and robust design of the sensors makes measuring possible even under cramped conditions.

Laser Sensor LAS

| LAS-T5 Series standard | LAS2-TM Series miniature |

|---|

| Ranges | 10 - 800 mm |

|---|---|

| Resolution | 2 µm |

| Linearity max. | ±6 µm |

| Frequency max. | 5 kHz |

| Output | 0...10 V, 4...20 mA |

| Protection class | IP67 |

| Download | Data sheet LAS2-TM miniature series up to 500 mm Data sheet LAS-T5 standard series up to 800 mm Installation guide | Teaching guide | CAD-data |

Laser Sensor LAR

| Ranges | 10, 30, 70, 160, 400 mm |

|---|---|

| Repeatability max. | 10 μm |

| Linearity max. | ±0.1 % |

| Frequency max. | 660 Hz |

| Output | 0...5 V, 4...20 mA, PNP, NPN |

| Protection class | IP67 |

| Download | Data sheet Installation guide CAD-data |

Laser Sensor LAH-G1

| Ranges | 4 - 300 mm |

|---|---|

| Resolution max. | 0.5 μm |

| Linearity max. | ±0.1 % |

| Frequency max. | 5 kHz |

| Output | 0...10 V; 3.2...20.8 mA; PNP; NPN |

| Protection class | IP67 |

| Download | Data sheet Installation guide CAD-data |

Laser Sensor LAW

| Range | 4 mm |

|---|---|

| Resolution max. | 0,06 µm |

| Linearity max. | ±2 µm |

| Frequency max. | 30 kHz |

| Output | 0...10 V / 4...20 mA / Ethernet TCP/IP |

| Protection class | IP67 |

| Download |

Laser Sensor LAV

| Ranges | 8 m, 50 m |

|---|---|

| Resolution max. | <5 mm |

| Linearity max. | ±25 mm |

| Frequency max. | 100 Hz |

| Output | 4...20 mA, IO-Link |

| Protection class | IP65 |

| Download | Data sheet Installation guide CAD-data |

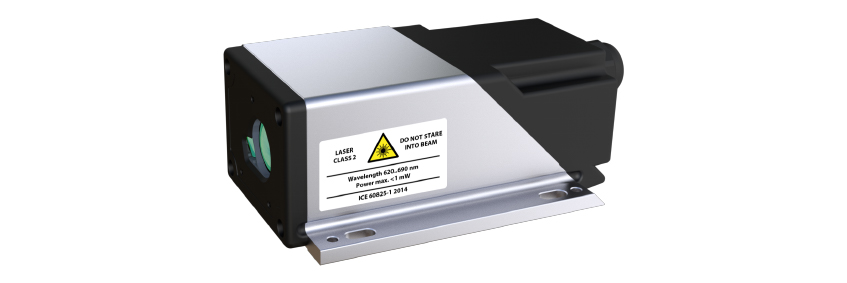

Long Distance Laser LDI

| Ranges | 0.05...500 m |

|---|---|

| Repeatability max. | ±0.3 mm |

| Linearity max. | ±1 mm |

| Frequency | 50 Hz |

| Output | 0...20 mA, 4...20 mA, RS232, RS422, RS485, SSI, ProfiNet, EtherNet/IP, EtherCAT |

| Protection class | IP65 |

| Download |

Long Distance Laser LLD-150

| Ranges | 0.2...150 m |

|---|---|

| Resolution max. | 0.1 mm |

| Linearity max. | ±3 mm, repeatability ±0.5 mm |

| Frequency | 10 Hz or 50 Hz |

| Output | 4...20 mA, RS232, RS422, Profibus |

| Protection class | IP65 |

| Download | Data sheet Manual LLD-150-RS232 Manual LLD-150-PROF2 CAD-data |

Measurement of complexe surfaces

In the automobile industry single components are joint to modules, which are assembled to the final product at a production line. Some of these modules have complex geometrical shapes, which are hard to detect with contacting sensors. Laser sensors and other non-contact transducers are well suited to measure these complex constructions. For example, the laser displacement transducer LAS controls if the dimensions of a headlight module comply with the tolerances to later assemble it in the production line. This way inconsistencies are detected and can be avoided in the future. Also these inconsistencies can be rejected easily, otherwise they would slow down the production line later on.

Laser displacement transducers - driving behaviour

The driving behaviour of a car is a decisive criterion in the purchase decision of a potential costumer. Because of this the driving behaviour of new developments and modifications is thoroughly checked by mean of distance measurement.

For this laser sensors are mounted to the chassis. The sensors high measuring frequency ensure that the number of measured values is sufficient for the analysis. The laser displacement transducer measures the distance between the chassis and the ground. The optical measurement principle of the sensors allows the analysis of the tilt of the car and the road holding.

Laser displacement sensor - level measurement

Level measurements are known as demanding measurement applications. Level measurement and distance measurement are important throughout industry and research. They are essential in the food industry, the plastics industry and the chemical industry. The material of which the level should be measured can be present in the three states of matter: solid, liquid or gas. The level can be measured by means of laser sensors if the material is in the state of liquid or solid. Liquid materials have to be at rest and non-transparent. Solid materials must not be reflective, because this might disturb the opto-electronical element or deflect the laser beam. If these requirements are fulfilled, the level measurement with laser displacement transducers is possible.

Laser distance sensors - storehouses

Today storehouses are commonly automated logistics centres. Within these logistics centres optical sensors are used more and more frequently. The high-level racks of these centres provide space for several thousand pallets. The goods are automatically controlled from the delivery to storehouse the storage to the delivery from the storehouse.

Modern gripper arms run automatically through narrow corridors and position the goods absolutely precise. At longer distances laser sensors monitor the clearance to position the goods intended space.

The triangulation principle is basic for this measurement method (exception LLD). The laser beam in the form of a small spot arrives on the surface of the target, while the detector of the system captures its position. The distance itself is calculated by means of the change of the angle. Achievable resolution and accuracy are therefore influenced mainly by the distance d: In proximity of the sensor, a large angular change a1 can be obtained, whereas larger values result in a smaller angle a2, thus in reduced accuracy (see drawing).

A photo diode array integrated in the sensor represents the receiver, high speed versions use a PSD element. The receiver is directly coupled to a micro-controller, being part of the system. This micro-controller analyses the light distribution on the element, calculates the exact angle and out of it the distance to the object. The calculated distance is either transferred to a serial port or alternatively is converted to a proportional output current. The micro-controller guarantees a very high linearity and accuracy. The combination of photo diode array and micro-controller allows a suppression of interfering reflections and ensures a reliable results even on most critical surfaces. The sensor automatically adapts to the surface colour by a change of its internal sensitivity. This way influences due to the target colour are nearly excluded. An integrated digital output is activated whenever the sensor does not receive enough light (pollution signal), or if no object within the measuring range can be detected at all.

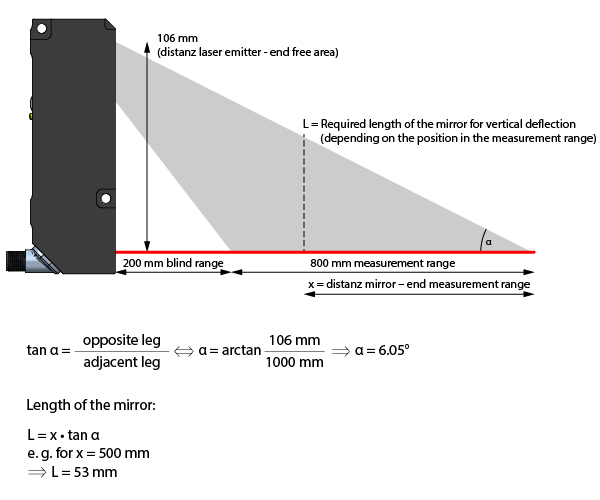

Laser and mirrors

When using a mirror, one must take into account that all rays travel via the mirror. This includes the laser beam and the light reflected from the object, which must travel back to the sensor.

If mirrors are used, note the following:

- A single mirror must be used. Two mirrors can tilt the optical axes of the transmitter and receiver, in which case a signal will no longer be received.

- The mirror should be located before the beginning of the measuring range. If it is within the measuring range, dirt on the mirror can cause the sensor to measure the distance to the mirror and not the distance to the object. If the mirror is within the measuring range, special attention must be paid to cleanliness.

- The mirror must overlap both surfaces (transmitter and receiver) as shown in the illustration so that all rays pass over the mirror.

- A surface mirror must be used. Normal mirrors have a layer of glass first, followed by the mirror surface. The glass layer may interfere. A surface mirror has the reflecting surface on its front surface.

- The reflectivity of the mirror should be approx. 90 %.

Laser distance transducers are mostly based on the triangulation principle. They are equipped with an opto-electronical element and are optimal suitable for the measurement of long distances while providing a high resolution. The internal signal analysis of the distance sensors allows them to work precisely regardless of the colour and most structures of the surface. Thanks to the optical measurement, laser displacement sensors are used in many different applications.

|

|||||||||||||||||||||||||||||||

|

MINIATURE |

|||||||||||||||||||||||||||||||

|

0...10 V 4...20 mA |

|

||||||||||||||||||||||||||||||

|

STANDARD |

|||||||||||||||||||||||||||||||

|

0...10 V 4...20 mA |

|

||||||||||||||||||||||||||||||

|

0...10 V 4...20 mA |

|

||||||||||||||||||||||||||||||

|

COMPACT |

|||||||||||||||||||||||||||||||

|

0...5 V 4...20 mA PNP / NPN |

|

||||||||||||||||||||||||||||||

|

REFLECTION |

|||||||||||||||||||||||||||||||

|

0...10 V 3.2...20.8 mA PNP /NPN |

|

||||||||||||||||||||||||||||||

|

DYNAMIC |

|||||||||||||||||||||||||||||||

|

0...10 V 4...20 mA PNP/NPN Ethernet |

|

||||||||||||||||||||||||||||||

|

LONG RANGE |

|||||||||||||||||||||||||||||||

|

4...20 mA IO-Link |

|

||||||||||||||||||||||||||||||

|

4...20 mA RS232 / RS422 Profibus SSI |

|

||||||||||||||||||||||||||||||

|

0...20 mA, 4...20 mA, RS232, RS422, RS485, SSI, ProfiNet, EtherNet/IP, EtherCAT |

|

|||||||||||||||||||||||||||||