Draw-wire sensors in waste management

29.03.2022

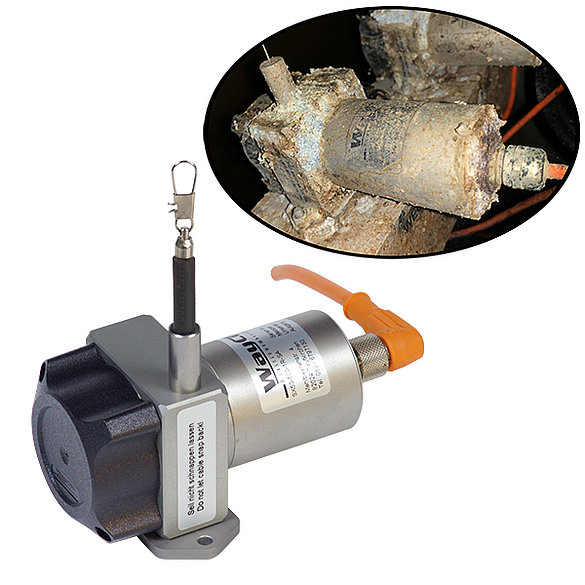

Draw-wire sensors from WayCon still provide measurement results after more than 10 years under extreme conditions. The sensor is exposed to highly aggressive media 24 hours a day, where other sensors would have had to be replaced long ago. In addition to the outstanding sealing of the electronic components, the SX50 series draw-wire sensor owes its continued functionality to the processing of high-quality materials and functional design.

In Germany alone, waste management employs about 35,000 people with an annual turnover of 40.6 billion euros (as of 2021). The volume of waste generated in 2019 was about 417 million tonnes (476 kg of household waste and 194 kg of residual household waste / bulky waste per head).

Recycling helps to achieve a recovery rate of 82%. However, 23.9 million tonnes of hazardous waste were generated. Construction and demolition waste amounted to 9.6 million tonnes and made up 40% of this hazardous waste. Another 6.7 million tonnes, or 28%, came from public waste- and wastewater-treatment plants, as well as from the treatment of water for human consumption and for industrial purposes. Oil waste and liquid fuel waste totalled 1.4 million tonnes, accounting for 6% of the hazardous waste.

The proportion of waste that cannot be recycled or is difficult to recycle is rising every year, despite constant improvements in recycling, which is why landfill sites are still indispensable today. It is therefore important that landfill sites harm the environment as little as possible. To this end, landfill sites are covered with geosynthetic sheets, which serve to compact, drain, filter and secure the waste. Geosynthetics are plastics that are manufactured in the form of non-woven and woven textiles, grids or composites, either completely or primarily using polymeric materials. These products can be either water-permeable or impermeable. To avoid the risk of waste slippage, draw-wire sensors are used to measure the position of the sheets. Draw-wire sensors have a highly flexible steel cable that is wound in a single layer around an ultra-light cable drum. A mainspring ensures that high tension is maintained and prevents the measuring wire from sagging. The encoder, which is connected to the cable drum by a shaft, supplies the desired signal (analogue, incremental or digital). The measuring wire is connected to the sheet and is routed through a robust tube to protect it from other objects and pressure during use. The sensors can be used in continuous monitoring as an early warning system, thereby reducing the risk of injury and damage to property. Draw-wire sensors come under significant strain while in operation. For example, polluted leachate can corrode the sensors’ housing.

For more than 10 years, GEOscope GmbH has been successfully using several WayCon SX50 series draw-wire sensors at a landfill site. Despite facing a high degree of wear, they still contribute to safety at the landfill site and deliver measurement readings. As can be seen from the picture, the housing of the sensors has been badly affected by corrosion. However, thanks to sensors with the IP67 protection class option, the electronics have been protected. WayCon is constantly developing its products further and now offers an ICP option for heavy wear to the material and sensor. The ICP option incorporates a hard anodic oxidation coating that protects the sensor from corrosion by aggressive substances through a hard-wearing, ceramic-like layer. This significantly extends the lifetime of the draw-wire sensors.

Technical information: data sheet SX50.

Further draw wire sensors: product page draw wire sensors.